|

"HOKUTO"

BLOWN FILM EXTRUSION LINE MODEL: HM50-65-50HS15FR |

|

FEATURE OF OUR MACHINERY We desing the machinery as "Simpler", "Faster", "Better" and "more cost-effective". "HOKUTO" BLOWN FILM EXTRUSION LINE ensures your business success at high-quality film market. |

|

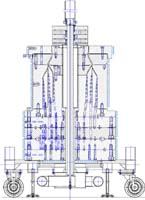

< OUTSIDE DRAWING OF 3 LAYER BLOWN FILM EXTRUSION LINE >

|

|||

|

|

Main Specification Extruders(for middle

layer)---1 unit integrated control

panel---1 unit *total temperature

control 19 zones thickness control---1

unit |

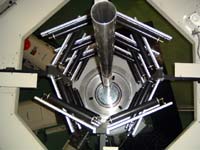

outside view  Extruders and die

Center of air-ring |

| IBC-Internal

Bubble Cooling *bubble size sensor: 4-ways *control type: by butterfly valve |

|

| Auto-profiling

system

*model: SmartLip350/32

segments |

SmartLip350 / 32segments Auto air-ring |

No-contact sensor head "VenPad" |

|

Air cooling

system(EUROCHILLER) |

|

|

Haul-off system *Oscillating

system *1st pinch roll *2nd pinch roll |

|

|

Winder:

separated slitting for long winding |

|

| Copyright(c) HOKUSHIN SANGYO CO.,LTD. All Rights Reserved. |